Does Foam Soundproofing Work?

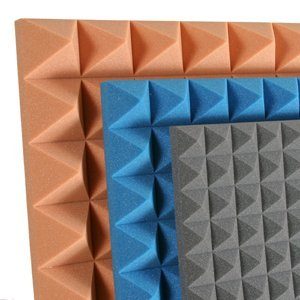

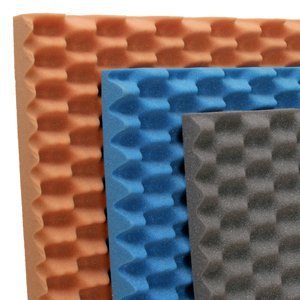

Foam soundproofing is a technique that reduces echoes and reverberations. Place foam sheets on the hard, flat surfaces that your speakers point toward or the walls people typically face when speaking. The foam converts sound energy into heat, then disperses it across its surface. Treating a room with acoustic foam will reduce ambient noise, improving sonic clarity.

What Kind of Foam Is Best for Soundproofing?

The best soundproof foam is thick, dense and porous.

Thickness and density work in tandem. A dense soundproofing material has plenty of mass to trap sound. The thickness helps, but the ideal thickness depends on the frequency you’d like to target. The best soundproofing foam setup uses a variety of thicknesses to target sound across the entire spectrum.

Pores help soundproofing foam contain noise. The pores are large enough to allow sound in, but as sound vibrates inside the panel, it loses energy. When it’s ready to reflect, it lacks the power to escape the pores.

There are also different kinds of soundproofing foam for different areas. For instance, a corner trap is the best kind of acoustic foam for the corner of a room. Low frequencies create a lot of pressure, which is problematic in the confinement of a corner. A thick corner trap can absorb and tame any low-end sound.

Learn More About Soundproofing Foam

Quiet Noise with Soundproofing Foam