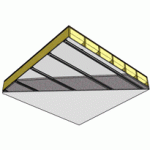

BEST Existing Ceiling Soundproofing Assembly

BEST Existing Ceiling Soundproofing Assembly

BEST Existing Ceiling Soundproofing Assembly Soundproofing Methods

Instructions for Installation – Best Existing Ceiling Soundproofing

1. Use a stud finder to locate the joists within the ceiling. Mark the joists with a chalk line.

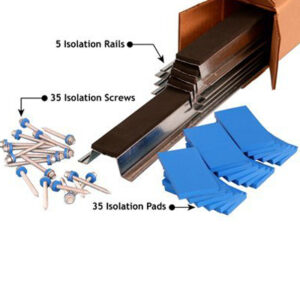

2. Using the chalk lines as a guide, install the isoTRAX® Soundproofing System onto the existing ceiling surface.

3. Install the Echo Absorber™ Acoustic Panels between the isoTRAX® rails.

4. Install ½ inch Type X gypsum board on to the isoTRAX® system with 1 ¼ inch fine thread drywall screws. Screws should be placed 8 inches apart. Leave a ¼ inch gap between the new layer of gypsum board and all adjoining wall, ceiling and floor surfaces.

5. Fill the ¼ inch gap with OSI® Pro-Series® SC-175™ Acoustical Sound Sealant.

6. Finish the gypsum board using common industry standards.

Note: For increased performance add another layer of 5/8 inch Type X Gypsum board.

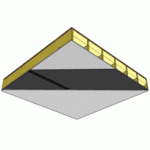

GOOD Existing Ceiling Soundproofing Assembly

Echo Absorber™ Acoustic Panel (Natural Blend – 1″x2’x4′)

$29.99

Echo Absorber™ Acoustic Panel (Natural Blend – 1″x4’x4′)

$45.99

Echo Absorber™ Acoustic Panel (Natural Blend – 2″x2’x4′)

$40.99

isoTRAX® Soundproofing System Ceiling Package

$241.85

OSI® Pro-Series SC-175 Acoustical Sound Sealant (Tube)

$17 GOOD Existing Ceiling Soundproofing Assembly

GOOD Existing Ceiling Soundproofing Assembly

GOOD Existing Ceiling Soundproofing Assembly Soundproofing Methods

Instructions for Installation – Good Existing Ceiling Soundproofing

1. Use a stud finder to locate the joists within the ceiling. Mark the joists with a chalk line.

2. Lay the ½ inch drywall face down on to a clean dry surface. Apply a ¼ inch bead PL Construction Adhesive around the perimeter of the backside of the drywall. Apply the adhesive approximately 2 inches from the edge of the drywall. Create an X pattern corner to corner and place a few 1 inch “globs” of glue with the field.

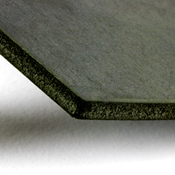

3. Place the Quiet Barrier® material onto the back side of the drywall. To ensure good contact with the adhesive, use a hand roller to apply pressure. Let the adhesive cure for 24 hours before installation.

4. Attach the drywall / Quiet Barrier® composite with 2 inch coarse thread drywall screws. Be sure the screws penetrate the joists within the wall assembly. Screws should be placed 8 to 12 inches apart.

5. Leave a ¼ inch gap between the new layer of gypsum board and all adjoining wall, ceiling and floor surfaces.

6. Fill the ¼ inch gap with OSI® Pro-Series® SC-175™ Acoustical Sound Sealant.

7. Finish the gypsum board using common industry standards.

Note: For increased performance add another layer of 5/8 inch Type X Gypsum board.

Quiet Barrier® HD Soundproofing Material (Sheet)

$145.99 $137.99

Free Acoustic Analysis

Free Acoustic Analysis

Soundproofing Questionnaire

Soundproofing Questionnaire