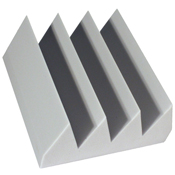

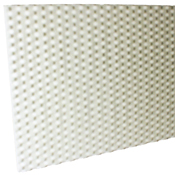

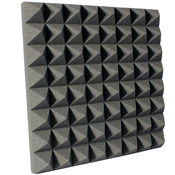

Engineered for performance — Acoustic Foam Panels are engineered to be an excellent sound absorption product at a low cost. Acoustic Foam Panels absorb sound generated at low, mid and high frequencies.

Quality — Acoustic Foam Panels are made with flexible, professional grade acoustic polyurethane foam. The foam keeps its color longer than other lower quality foams. Acoustic Foam Panels are firmer than other acoustic foam products on the market, which adds protection against rips or tears. The foam is consistent in density and firmness so acoustic performance will also be consistent.

Ease of Installation — Acoustic Foam Panels are lightweight and can be attached to a variety of surfaces. No special tools or materials are needed. Acoustic Foam Panels are available with a Pressure Sensitive Adhesive (PSA) backing for an easy peel-and-place application.

Fiber Free — Acoustic Foam Panels are safe to use in clean room, medical and computer equipment environments.

Flammability — Acoustic Foam Panels are manufactured from polyurethane foam that has a flammability rating of UL94 HF-1. Before choosing this product, be sure the flammability rating passes your local building code for exposed materials. For the best flammability rating see our Class A™ Acoustic Foam Panels.

Details

Great For:

- Automotive Cabs

- Ceiling tiles

- Clean Rooms

- Compressor Enclosures

- Computer and Server Rooms

- Engine Compartments

- Equipment Enclosures

- Gun Ranges

- Machine Enclosures

- Manufacturing facilities

- Medical Facilities

- Office Equipment Rooms

- Utility Rooms

Product Availability

Special Order Thicknesses starting at 1/2 in.

Special Order Sizes – Tell us what you need.

Call 1-866-949-9COW for details.

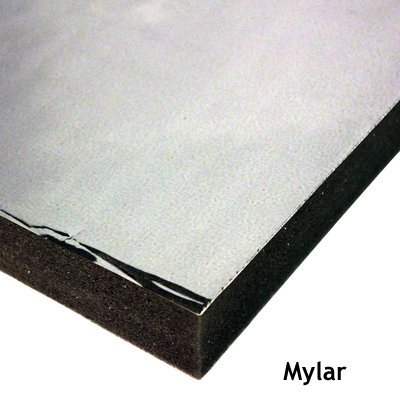

About Mylar® Facing:

Mylar® is an extraordinarily strong polyester film with superior strength, heat resistance, and excellent insulating properties. This product has a bright silver finish that has excellent light reflective qualities.

Pros:

- Heat reflective

- Good to reduce internal reverberations in enclosure

- Increased radiant thermal resistance

- Excellent abrasion resistance

- Light reflective

Cons:

- Easily punctured with sharp objects

- Extended delivery dates

- Special order only