Sound Absorption Materials

Sound Absorption Materials

Browse the best sound absorbing materials from Soundproof Cow. We offer various types of sound absorbing materials for homes and commercial buildings.

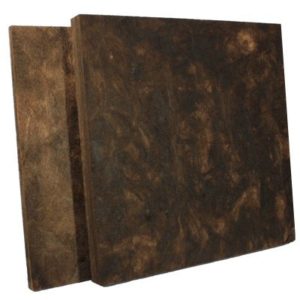

Noise absorbing materials reduce echoing and reverberation in a room by limiting reflection. Sound bounces off any hard surface on impact, but sound absorption materials soften the blow. Our absorption products feature soft, porous materials like foam, fiberglass and cotton that welcome sound in but make it tough to get out.

Sound loses energy trying to escape these materials, reducing what reflects after impact. Your indoor space will feel quieter, allowing you to enjoy better sound quality when listening to the television, speaking with friends or mixing your latest single. Use our absorption products in your home, office, church, medical facility, school, home theater, restaurant or any other indoor space.

Sound Absorption for Any Application

We offer numerous types of sound absorbing products. Our acoustic foam panels and acoustic fiberglass panels install on walls, while hanging baffles suspend from the ceiling. An acoustic partition is an excellent sound absorber that you can move anywhere in your home or office. Products like acoustic cotton and water resistant panels offer unique solutions for select applications.

Request an acoustic analysis or contact us online for more on how to use our absorptive materials.

- Site Credits

- Sitemap

- Privacy Policy

- Copyright © 2025. All Rights Reserved