A soundproofing project lives or dies by the materials you use.

In most construction or renovation projects, it makes sense to let your general contractor choose the materials. But soundproofing is different. It is not just about insulation or drywall; it is about how specific materials work together in a layered system to block sound transmission through walls, floors, and ceilings.

Handing off the material decision is a common, and costly, mistake.

This article explains why you should choose and specify your soundproofing materials, even if you are hiring a contractor for the installation. You do not have to do it alone. Our acoustic experts are here to help you build the right plan for your project.

Why the Right Materials Matter

Soundproofing materials are selected based on what type of sound you want to block and where it is coming from. Sound moves in different ways, and different materials address different challenges:

- Mass blocks airborne noise like voices and TV. Try Quiet Barrier® Mass Loaded Vinyl Barriers (MLV) to add mass. MLV is a dense, flexible sheet that adds weight to walls, ceilings, and floors to reduce sound transmission.

- Damping reduces structural vibration in walls and floors. Use Green Glue Noiseproofing Compound between layers of drywall or subfloor to reduce structural vibration.

- Decoupling prevents vibration from moving through framing. Sound isolation clips create a separated (or “floating”) drywall channel so the drywall no longer sits directly on the studs.

- Absorptive insulation prevents the wall cavity from resonating like a drum and absorbs sound energy passing through. Quiet Batt® Soundproofing Insulation is a high-density cotton batt designed for this role.

These materials work together as a system. Using one without the others, or swapping one out with a “similar” product, can cause a significant drop in performance.

Why Homeowners and Small Business Owners Rely on Contractors

Contractors manage the entire build—framing, drywall, flooring, plumbing, and more. It is natural to assume they will handle soundproofing, too.

But most general contractors are not soundproofing specialists. Their purchasing decisions are often influenced by:

- What is readily available from local suppliers

- What is easiest to install

- Price pressure to keep the overall bid low

Add to that the fact that many soundproofing materials ship via freight on pallets, and homeowners understandably hand over the reins.

The issue? Without clear instructions from you, a contractor may choose something “close enough,”—which may not meet your expectations once the room is finished and the noise is still transferring between spaces.

The Problem With “Equivalent” Alternatives

This is where some projects go sideways. A contractor or supplier might say, “This is basically the same thing.” But in soundproofing, “close enough” often is not good enough.

Examples:

- Mass Loaded Vinyl MLV varies in density. A product rated at 1/2 lb per square foot (psf) provides significantly less sound blocking than 1 lb or 2 lb psf versions like Quiet Barrier® HD (2 lb psf).

- Damping Compounds: Generic “soundproof glue” or construction adhesive may not have the viscoelastic damping properties of Green Glue, which has been independently tested in full wall assemblies and is proven to convert vibration into heat.

- Isolation Clips: Many clips marketed as “soundproofing” are not load-rated (tested to safely support the weight of drywall) or acoustically tested.

- Insulation: Not all insulation is soundproofing insulation. Standard insulation may look similar, but it will not perform like Quiet Batt®, which has higher density and absorption properties.

Unless a substitution matches weight, damping performance, absorption coefficient, and installation method, it is not truly equivalent.

Why Homeowners Should Specify What They Want

No one understands your noise problem better than you do. You hear it every day. You know:

- Where it comes from (neighbors, kids, traffic, plumbing)

- What times is it worst

- How it affects your life or business

That knowledge should guide your material choices. When you specify your materials:

- You target the actual noise problem (e.g., airborne vs. impact noise)

- You avoid generic or underperforming substitutions

- You define clear expectations for your contractor

- You ensure that the system works as intended

This is not second-guessing your contractor—it is giving them a clear blueprint to follow.

How to Choose the Right Materials

You do not need an acoustics degree, reach out to our experts for custom support, or follow a simple process for selecting the right materials for your project:

- Identify your noise type

- Voices, TV, music = airborne noise (travels through the air)

- Footsteps, dropped objects = impact noise (vibration transmitted through floors)

- Pipes or HVAC = both airborne (whooshing, rattling) and structure-borne vibration (transmitted through framing and ductwork)

- Match materials to noise

Use our material soundproofing guide to select the right combination of mass, damping, decoupling, and absorption. For example:

- Wall blocking neighbor noise = Quiet Barrier HD + Green Glue + RSIC-1 Clips + Quiet Batt

- Floor blocking footsteps = Quiet Barrier HD under subfloor + Green Glue between subfloor layers + Quiet Walk underlayment under finished flooring

- Check specifications

- Review product weight (lbs, psf), thickness, density, and application method. Make sure they match your wall or floor assembly.

- Verify compatibility

- For example:

- Green Glue requires 1-2 tubes per 4×8 sheet of drywall (use 2 tubes for maximum performance)

- MLV must be installed with overlapped seams and sealed with acoustical caulk

- RSIC-1 Clips must be spaced 48″ apart horizontally and on every stud vertically

- For example:

Still unsure? Fill out our free Acoustic Analysis and we will walk you through it.

Deciding Who Should Order the Materials

Once the materials are chosen, either party can order them:

When the Homeowner orders:

- It ensures accuracy. No substitutions will be made.

- Delivery can be tracked and inspected.

- Materials will arrive before work starts.

When the contractor orders:

- It simplifies freight coordination.

- Materials are staged onsite.

- There are fewer handoffs and a smoother workflow.

Either works—but you should always be the one to specify what materials you need for your project.

What to Expect With Freight Delivery

Most soundproofing products do not ship via regular parcel carriers. They arrive on pallets via freight.

What that means:

- The carrier will deliver your acoustic materials curbside or to your driveway, not inside your space.

- Someone must be available to receive and move the shipment.

- Some materials (like insulation batts or MLV sheets) are heavy and bulky.

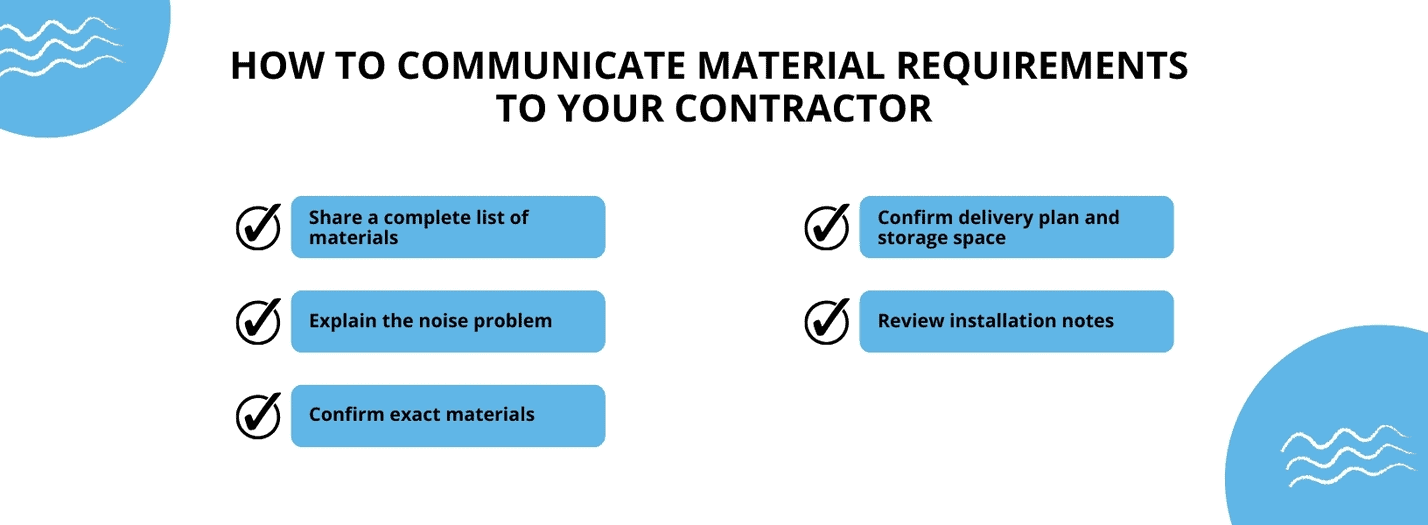

How to Communicate Material Requirements to the Contractor

A quick conversation before work starts can save you time and money.

Here is what to do:

- Explain what type of noise issue you are addressing.

- Provide a complete written list of product names, links, and quantities.

- Ask your contractor to confirm they are using those exact materials.

- Review any install requirements (e.g., Green Glue needs 2 tubes per 4×8 sheet, clips need to be spaced at specific intervals).

- Confirm delivery location, timing, and storage plan.

Print the install guides if helpful—we have PDFs for every product.

When to Contact Soundproof Cow

Reach out to us if:

- You are not sure what materials will solve your issue.

- You are comparing two different approaches.

- Your contractor wants to substitute something.

- You are soundproofing multiple surfaces (e.g., walls and floors) and need a full system plan.

We will help you sort through options and build a list that fits your space, your goals, and your budget.

Start an Acoustic Analysis or call us directly—we love this stuff.

Soundproofing is not just about buying “soundproof” materials—it is about assembling the right system for your exact problem.

You do not need to do the install yourself. But if you choose your materials up front, your contractor can execute a proven plan—and you will get the quiet you paid for.

Ready to start? Browse our wide selection of soundproofing materials. We are here to help you build a better assembly.