Economical — Costing about 80 cents per square foot, a layer of Green Glue is the most economical sound isolation product around, as well as one of the best.

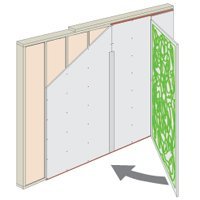

Ease of Installation — Since Green Glue is intended to be sandwiched between two sheets of building materials such as drywall, it eliminates the need to remove existing wall and floor materials. Because of its thin consistency (like ketchup), a tube of Green Glue can be easily dispensed in 15 seconds. Green Glue will not flow off a board when installing. No specific coverage pattern is necessary to ensure excellent results. No measuring or troweling. A larger tip opening (3/8” opening) can be used to speed application without concern for performance.

Environmentally Friendly — Green Glue Noiseproofing Compound is non-toxic, non-carcinogenic, and very low in VOCs (it’s less than 5 grams per liter/compliant in all 50 states and worldwide). It does not contribute to mold growth and has almost no odor. Green Glue Noiseproofing Compound can be easily cleaned up while still wet with soap and water.

Excellent Flammability Rating — Green Glue Noiseproofing Compound has been validated for use in any fire rated assembly according to the International Building Code. Using Green Glue Noiseproofing Compound will not affect the fire rating of the area to which it’s applied.

Details

Great for:

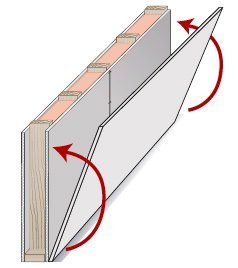

- Walls – Gives customers the ability to soundproof walls without removing the existing construction. Green Glue can be used between virtually any rigid building materials to dissipate sound waves.

- Floors – Can be used to increase the performance of Impact Barrier QT, Proflex 90 and Step Above Soundproofing Underlayment. Green Glue can be added to subfloor assemblies to dissipate vibrations created by “footfall”.

- Ceilings – A great way to soundproof ceilings with a minimal loss of height. The .5mm thickness of the applied product minimizes clearance issues.

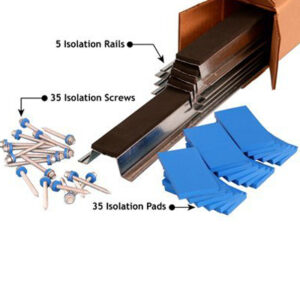

- New Construction – Easy to use with Quiet Batt Soundproofing Insulation and Isotrax Sound Isolation Systems to increase performance. Green Glue dissipates airborne sound and vibrations making it a viable addition to any soundproofing assembly.

- Building Upgrades – Adds soundproofing to existing walls and ceilings without demolition. Green Glue is easy to clean and installs over existing construction. This minimizes dust and debris as well as down time.

- Renovations – Economical way to add soundproofing to walls and ceilings without removing existing construction.

- Residential – Dissipates both airborne sound and vibrations. Green Glue can be used to minimize sound from room to room or from upstairs to down stairs.

- Commercial – This material is validated in all fire rated assemblies. It can be used on New or Existing walls, ceiling and floors.

How Green Glue Works:

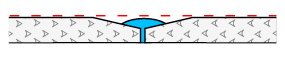

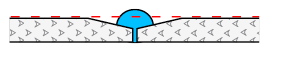

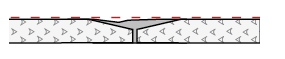

In a constrained layer damping system, sometimes referred to as CLD, a damping material is sandwiched between two other (usually stiff/center of the “sandwich” is sheared rigid) materials. For example, Green Glue sandwiched between two layers of drywall. Damping occurs when the viscoelastic center of the “sandwich” is sheared.

When bent, shear forces pull and stretch on the damping material. Under these conditions, the unique polymeric construction of Green Glue very efficiently converts this mechanical energy to heat. The vibration energy is not isolated, it’s dissipated and gone.