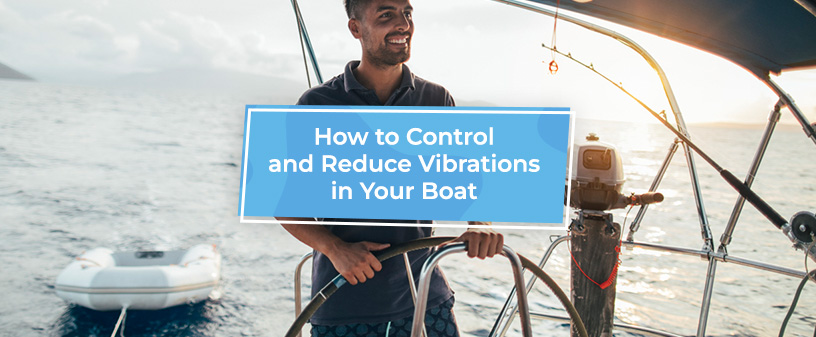

Reducing vibrations in a marine vessel is a bit more complicated than you might assume. Luckily, there are quite a few effective solutions you can implement. We will help you identify the sources of boat vibrations and recommend a few practical solutions so that you can seize the MOO-ment on the water!

What Causes Vibrations on a Boat?

The first step to a smoother and quieter cruise is figuring out where those pesky vibrations come from. They could be standard effects of the engine at work or the result of mechanical issues. If engine troubles cause worsening vibrations, you will need to prioritize maintenance and repairs.

The Engine Room

The primary source of vibration and shaking is the engine room. As engines run, they cause constant vibrations that create shaking and a humming sound. If you have a larger vessel, the generator set, or genset, is another source of vibration. This engine powers the generator onboard, which powers the AC system and other features.

The engine room pumps and compressors also move about and generate quite a bit of vibration that moves through the structures holding them in place. The mounted fuel tanks will also shake and rattle as the vibrations in the engine room move through all the structures.

Engine Misalignment

While some level of vibration is normal, excessive vibration and differing frequencies can spell trouble. They can also seriously put a damper on your boating excursion. Monitoring vibration levels and frequencies is wise to keep your boat’s engine in check.

If the main engine is even slightly misaligned, you might notice the shaft wobbling while the engine is running. The shaft-to-bearing alignment could also be off. If the shaft is off-center to the opposite end, it will not be parallel to the bearing bore. The mounts should be parallel to the boat’s centerline, while the studs should be vertical to the base.

When engine misalignment causes bad vibrations, you will want to schedule maintenance and repairs with a professional boating mechanic. Alignment issues can lead to rapid wear and tear, which can result in transmission failure and other costly concerns.

Loose Engine Mounts or Connections

Loose engine mounts, hoses and other connections to the engine can also lead to worsened vibrations and increased wear and tear on the engine. While general wear and tear can shift the mounts and connections out of place over time, incorrect installation can also lead to this issue.

Inspect the mounts and connections for loose clamps and bolts. You should also inspect the hoses for signs of wear and tear. When the engine mounts loosen, the entire structure can shimmy out of place, leading to misalignment. If this is the case, you will need to reach out to your boat mechanic to solve the issue.

Engine Corrosion or Damage

Corrosion or damage to engine parts is pretty easy to spot but less easy to fix. You will need to reach out to a mechanic to replace these parts and restore proper function. If your boat is due for a maintenance service, this is the perfect time to mention any extra loud vibrations so that your mechanic can take a look.

Even after solving potential mechanical issues, your engine room will still vibrate and send shakes and shivers throughout your vessel. Never fear — you can find ways to control and reduce these standard vibrations.

Ways to Control and Reduce Vibrations on a Boat

Soundproofing materials offer a practical solution to dampen boat engine vibrations and other noises. These legen-dairy products can help out:

- Quiet Barrier® HD Soundproofing Composite: The engine compartment must be as airtight as possible to reduce noise caused by vibrations. Soundproofing the hard surfaces of the compartment can deaden sounds by minimizing vibrations. Install a foam soundproofing barrier like the peel-and-stick Quiet Barrier® HD Soundproofing Composite to encase the compartment.

- Quiet Barrier® MD Soundproofing Material: You can also use the Quiet Barrier® MD Soundproofing Material to cover the walls and ceiling of the engine room to dampen airborne sounds.

- Quiet Barrier® Acoustic Quilts: When it comes to the floors, we recommend Quiet Barrier® Acoustic Quilts. You can also drape these quilts over hatches or use them to line the hull.

- Sealants: Soundproofing sealant products trap sounds and prevent them from escaping through panels. These handy sealants can also seal gaps around pipes that travel through the engine compartment. They are also helpful for ensuring the spaces around doors and hatches do not let sounds out. It is worthwhile to seal all rooms on board with the same sealant product.

- Acoustic foam panels: The mounted fuel tanks in the engine room are another source of noisy vibrations. Encase this structure with an acoustic foam panel with aluminum facing — the outer aluminum layer will protect the inner foam layer from deterioration.

Shop Boat Soundproofing Materials

Tips to Control and Reduce Outboard Motor Vibrations

If you have a smaller boat powered by an outboard motor, you will need to use different soundproofing techniques. First, make sure the outboard motor is installed correctly. If not, the engine may wiggle around and cause more vibrations.

If the motor is mounted correctly, you can use acoustic panels with aluminum facing to soundproof the cowling that covers the outboard motor. Because the vibrations come from inside the motor, soundproofing the cover can minimize noise. Cover the inside of the cowling while carefully avoiding the air vents to prevent harming the engine.

You can also use Silent Running SR-500 to cover the outboard motor. This high-performance coating can convert vibrations and noise into low-grade heat that quickly disappears.

Schedule a Free Acoustic Analysis With Soundproof Cow

Whether you are hoping to reduce engine vibration sounds coming from your boat’s engine room or need solutions to quieten your outboard motor, Soundproof Cow has an expansive range of high-quality soundproofing materials for various applications. With our noise-dampening product selection, you can enjoy a smoother, more peaceful sailing experience.

If you need more help finding the right products for your silencing project, reach out to us. We will help you find the best soundproofing solutions for your specific boat and create a solution that suits your needs. Contact us online, or schedule a free acoustic analysis today.