Features / Benefits of Proflex 90

Dual Soundproofing Function — PROFLEX™ 90 reduces noise from impact, such as foot fall, and reduces airborne sound transmission, such as noise from voices, TV’s and stereos. PROFLEX™ 90 has an Impact Insulation Class (IIC) rating of 68 and a Sound Transmission Class (STC) rating of 72. Please see the Technical Data sheet for more information.

Ease of Installation — PROFLEX™ 90 is a peel and place application which decreases installation time. Simply roll out the product, measure and cut, then peel the protective backing and place. A heavy roller is then used to properly bond the sound control membrane to the sub-flooring. It is recommended that PR11 Water Based Primer be used before PROFLEX™ 90 is installed to seal flooring substrate. Once applied, there is no waiting time for the installation of floor covering materials.

Protects from Cracks — PROFLEX™ 90 bridges cracks and controls joints up to 3/8” wide, eliminating the transfer of cracks to the finished flooring.

Not Condition Sensitive — PROFLEX™ 90 may be installed in interior and exterior locations, as well as locations which are exposed to moisture.

In-stock — We stock all advertised sizes of PROFLEX™ 90. Most products are shipped the same day they are ordered and arrive at your project in three business days, depending on location and size of order.

Details

Great for:

- Hard Wood Floors

- Stone Floors

- Tile Floors

Acoustic Data

| Product | STC* | IIC* |

|---|---|---|

| PROFLEX™ 90 | 72 | 68 |

* STC = Sound Transmission Class * IIC = Impact Insulation Class

Recommended Substrates

May be applied over properly prepared substrates including (but not limited to): concrete slabs; pre-cast panels; lightweight toppings; patching, leveling, and repair compounds; cement backer boards; terrazzo; ceramic tile; plywood; OS.

Additional Information

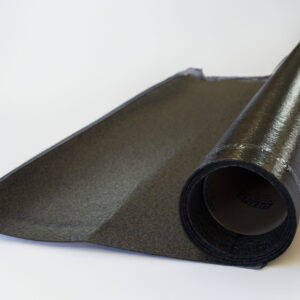

PROFLEX™ 90 is a self-bonding, reinforced, 90 mil-thick elastomeric crack isolation and sound reduction membrane. The membrane forms a permanent bond to concrete, steel, or wood substrates and is compatible with most cementitious, epoxy, and urethane adhesives.

PROFLEX™ 90 bridges cracks and controls joints up to 3/8” wide, eliminating the transfer of cracks to the finished flooring.

PROFLEX™ 90 is specially designed to be used under approved thin set mortars and adhesives for interior and exterior applications of ceramic tile, stone, and brick, and for interior applications of wood flooring. Other applications also may be suitable, please contact our acoustic Consultants for additional information.

PROFLEX™ 90 sound reduction properties are for floors requiring a minimum Impact Insulation Class (IIC) of 68 and Sound Transmission Class (STC) of 72, as tested in accordance with American Society for Testing and Materials (ASTM) Standards E90-02, E989-89, and E492-90. Testing for PROFLEX™ 90 was conducted on 8” concrete slab with an acoustic ceiling.

PROFLEX™ 90 offers limited warranty terms up to ten (10) years, based on the system of materials used to install the finished flooring products. Contact us for specific warranty terms and conditions.

Cautions and Limitations

Substrate must be primed with PROFLEX™ Primer. Protect Primers from freezing.

Follow PROFLEX™ installation instructions, all TCNA (Tile Council of North America), NWFA (National Wood Flooring Association) technical specifications and guidelines.

Consult with manufacturer of thin-sets, mortars, and adhesives to determine compatibility with their product. Mortars shall be at a minimum ANSI 118.11 specification.

Impervious tile (less than 0.5% absorption) may require a 48-hour cure prior to grouting. The mortar will be sandwiched between two non-absorptive materials and will require additional cure time.

Cooler weather will also increase set time.

Not for use over expansion joints (structural design joints) or structural (out-of-plane) movement cracks.

Not recommended for use on concrete floors when hydrostatic pressure is present. We recommend testing the substrate prior to installation of product using a Calcium- Chloride (CaCl) test kit. Maximum 1/4” seam for crack isolation.

Perimeter expansion of 1/4” minimum must be maintained for warranty.

Why Use Proflex 90 Flooring Underlayment?

Why Use Proflex 90 Flooring Underlayment?