Is your loud boiler making you moo-dy? Soundproofing a boiler room can help dampen or greatly reduce disturbing noises. Try out one of our six techniques to reduce the noise from your boiler cupboard or soundproof a room for peace and quiet.

Why Boilers Make a Lot of Noise

It is normal for boilers to make noise. They are heating up water and pumping, so humming, whistling and ticking are expected. When you turn the boiler on, you can expect a loud popping sound because the water is starting to heat up.

Once it is up and running, you will notice a whirring noise. This comes from the heat pump circulating the water. Modern boilers make a clicking sound as the valves switch on and off inside.

It is important to know which sounds are normal before you soundproof it. You would not want to block out a noise that may indicate something is wrong. These sounds are typically a cause for concern:

- Loud banging

- Excessive whistling

- Loud gurgling

If the noises are concerning, call a professional to check your boiler before you soundproof the enclosure. Once soundproofing is completed, check on the sounds occasionally to ensure they are not worsening. Although noises can be worrying, boilers do have safety mechanisms, so they are unlikely to harm the boiler.

However, the loud wallops and thumps can disturb your peace. Whether you are working on a high-focus project or trying to catch up on your favorite show, the loud boiler will be your background noise. If you can not stand another minute sound, there are effective solutions that can reduce or remove the noise.

How to Soundproof a Boiler

There is no one-size-fits-all soundproofing option. If you plan on DIY-ing it, ensure you follow the product instructions or talk to an expert at Soundproof Cow. Here are some methods to consider:

1. Stud Walls

Stud walls are an almost perfect way to eliminate boiler noise. In a staggered or decoupled stud wall, each sheet of drywall has its own stud that connects to the wall material, blocking vibrations from traveling through the wall and increasing sound-dampening properties.

Build stud walls in your boiler cupboard and add acoustic insulation to fill the gaps in the stud walls. This creates a thick, impenetrable layer that sound waves will not pass through easily. The Quiet Batt® Soundproofing Insulation is ideal when paired with the isoTRAX® Soundproofing System, eliminating the boiler’s vibrational noise.

While this method does involve the most work, it is our number-one recommendation in most cases because it is a long-term, effective fix.

2. Acoustic Mineral Wool

Mineral Wool is a tried-and-true method for sound and heat insulation. It is made of fine fibers that use thermal insulation to capture energy like heat and sound. It has absorbent properties that trap noise. When sound waves hit mineral wool, they transform into heat. The heat disperses within the panel, preventing noise from passing through.

Ensure you get the right fiberglass insulation material for sound, as some are used solely for heat insulation.

3. Soundproof Blanket

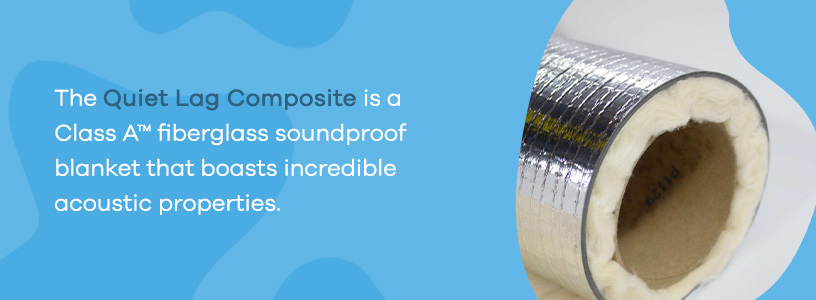

Are you wondering how to soundproof your boiler room with the best results? Use a soundproof blanket. It is cost-effective, simple and effectively dampens boiler sounds.

The Quiet Lag Composite is a Class A™ fiberglass soundproof blanket that boasts incredible acoustic properties. It is easy to install and works for heavy-duty soundproofing projects or DIY at-home soundproofing. The easiest way to use this blanket is to fit it along the door of your boiler cupboard.

4. Door Sweep

Soundproofing the boiler cupboard door can greatly limit noise. It is an excellent method for soundproofing hanging cupboards and solid hall cupboards.

Quiet Door™ door sweeps are made from aluminum and have silicone seals that effectively trap noises. They keep the boiler noises inside the cupboard and offer an affordable sound absorption method.

5. Soundproofing the Room

Maybe your property has several boiler rooms or you just want to quiet a specific space. Consider soundproofing the room or enclosure. Your boiler will still hum and whir, but you can enter a noise-free room. There are many ways to soundproof a wall, but these options are the most effective:

- Add mass: Apply a high-density material to the wall. It dampens vibrations and effectively reduces sound transfer. Use Quiet Barrier® Soundproofing Material for easy application. It is heavy enough to add a significant amount of mass and has a straightforward peel-and-stick backing. Ensure you seal all exposed cracks with Quiet Barrier® Tape or OSI® Pro-Series SC-175 Acoustical Sound Sealant.

- Use cotton batts and insulation: Cotton batts reduce noise levels, but they do not completely block sound. They work by preventing energy from bouncing back and forth, reducing the overall noise level. If you want more effective insulation, opt for the Quiet Batt® Soundproofing Insulation product line, which reduces noise and provides thermal insulation. You can enjoy the energy-saving benefits in your temperature controlled, quieter room.

- Apply sound isolation systems: Sound isolation systems are one of the best soundproofing methods. They can almost perfectly isolate sound from one room to the other. The isoTRAX® Soundproofing System prevents common studs from traveling through the drywall. It has an easy peel-and-stick applicator and the added benefit of increasing wall strength.

Hit the Moote Button on Your Boiler Room With Soundproof Cow

Boiler rooms naturally make noises that can disturb your environment. Loud boilers fill the day and night with pesky background noises. The good news is that Soundproof Cow can help you with our udderly awesome line of soundproofing materials, which bring silence to commercial and residential spaces.

We understand that every situation is different, and our team will work with you to find resolutions to your soundproofing needs. We know that without our amazing customers (like you), we would not be where we are today.

Feel free to reach out and let us help you find what you need. You can also check out our gallery to see our soundproofing solutions in action.