Superior Acoustic Performance — Udderly Quiet® Acoustic Panels are our premium sound absorption product and can be used anywhere reverberation (echo) is an issue. Our acoustic panels will improve speech intelligibility, improve production and improve any listening or recording environment. Udderly Quiet™ Acoustic Panels absorb noise generated at low, mid and high frequencies.

Exceptional Quality — Udderly Quiet® Acoustic Panels are meticulously hand-made by experienced craftsmen that take pride in the product they build. Only the highest quality materials available are used to make this highly finished professional product.

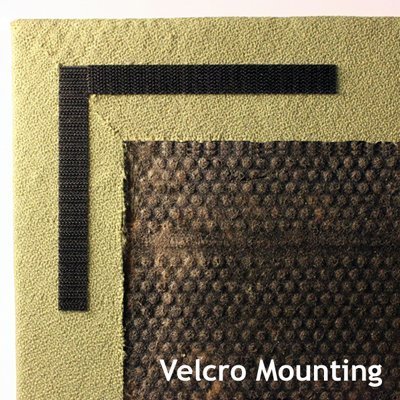

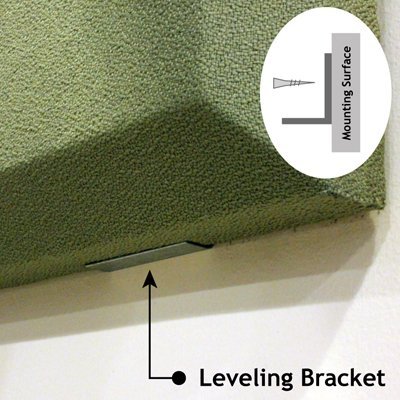

Ease of Installation — Udderly Quiet® Acoustic Panels are light weight and can be attached to a variety of surfaces. Basic hand tools and a limited amount of construction know how is all that are needed to ensure a proper installation. Udderly Quiet® Acoustic Panels can be cut or trimmed on the job site with simple hand tools. Our Acoustic Panels can be mounted permanently with adhesive or temporarily with Hook & Loop or Z-Clips.

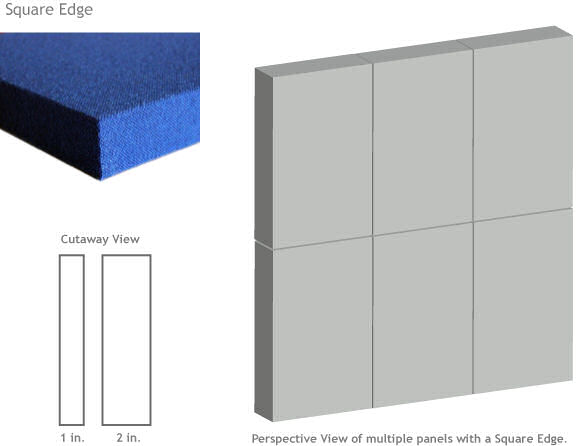

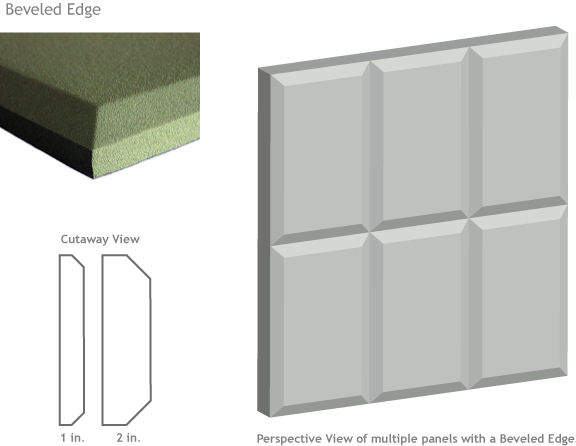

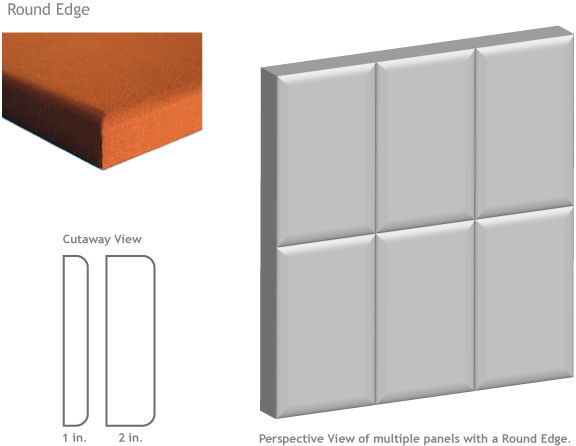

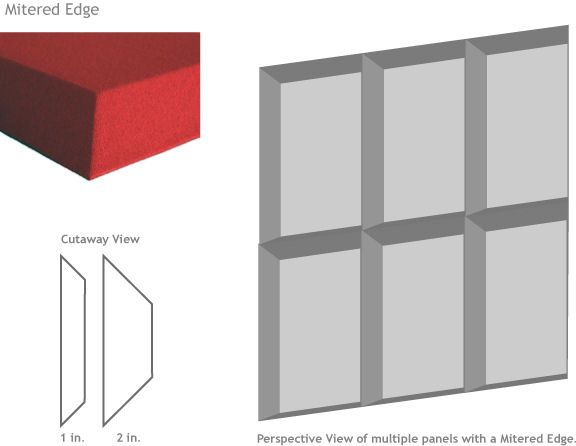

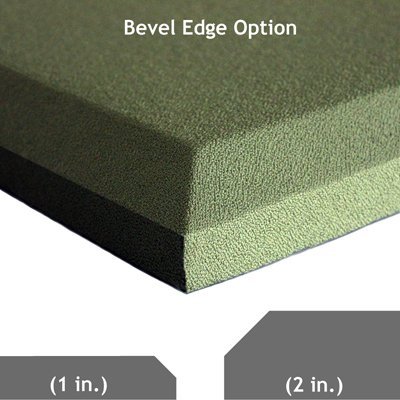

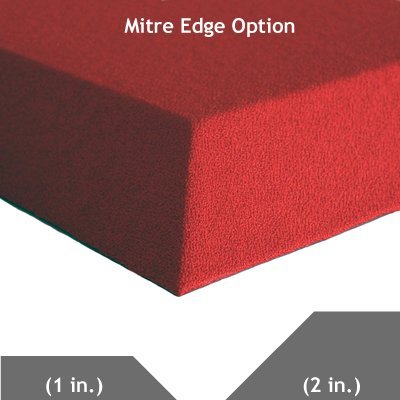

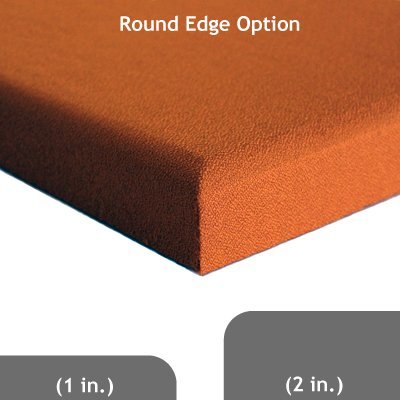

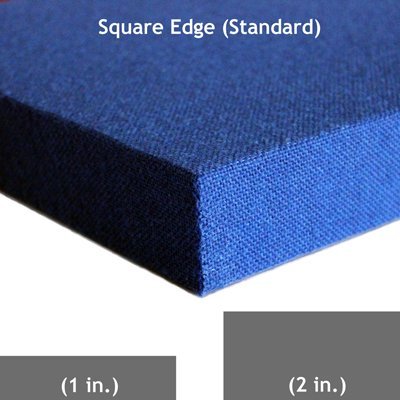

Endless Design Potential — Udderly Quiet® Acoustic Panels are custom built to your specifications. Architectural interest is added by ordering our panels with square, beveled or rounded edges.

Fabric Covering Variety — Udderly Quiet® Acoustic Panels are available with an endless variety of fabric options. Choose the fabric color and texture that best matches your existing décor. If desired, we will match your fabric of choice.

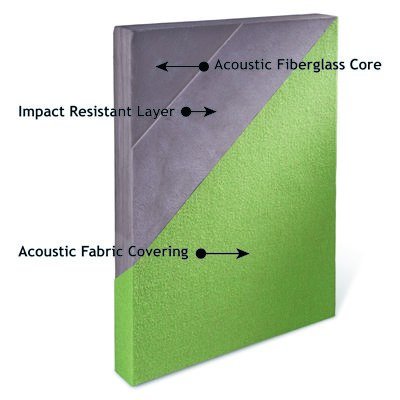

Durability — Impact Resistant Udderly Quiet® Acoustic Panels have a dense layer of Acoustical Glass Mineral Wool that protects the panel from impact.

Excellent Flammability Rating — Our Udderly Quiet® Acoustic Panels have a Class A™ flammability rating. This product passes most building code flammability requirements for exposed materials.

Versatile — Udderly Quiet® Acoustic Panels are a great office accessory for posted messages or need to know information. Panels covered with the FR701 fabrics work with hook & loop Velcro® and are tackable.

Green Information:

Our Acoustical Glass Mineral Wool is made with 50% Recycled Post-Consumer materials. In other words, the same bottles you recycle every week!

The other 50% of our Acoustical Glass Mineral Wool is made from one of the most abundant renewable resources on the planet- sand!

The Binder used in our Acoustic Glass Mineral Wool reduces embodied energy by 70%, which means there’s 70% less binder agent needed when compared to other glass wools and acoustic fiberglass products.

All of our Acoustic Fabrics are 100% Recycled Polyester.

Other Acoustic Panel Models

- Udderly Quiet® Acoustic Panel – 200 Series

- Udderly Quiet® Acoustic Panel – 250 Series

- Udderly Quiet® Acoustic Panel – 300 Series

- Udderly Quiet® Acoustic Panel – 350 Series

- Udderly Quiet® Acoustic Panel – 400 Series

Acoustic Data

| THICKNESS | COVERING | DENSITY | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC* |

|---|---|---|---|---|---|---|---|---|---|

| 1 INCH | fabric | 7lbs & 18 lbs | .31 | .55 | .89 | 1.07 | 1.05 | 1.15 | 0.90 |

| 2 INCH | fabric | 7lbs & 18 lbs | .28 | .69 | 1.07 | 1.11 | 1.06 | 1.08 | 1.00 |

* NRC = noise reduction coefficient

Acoustic Panel Edge Profiles

Acoustic Panel Corner Options

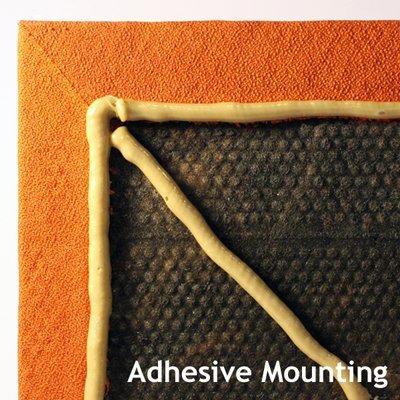

Adhesive mounting is ideally suited for permanent applications requiring speed and ease of installation. This type of installation requires little to no layout time depending on various field conditions. Use this method if there is a potential for impact or other stresses. The adhesive method provides the strongest bond between panel and wall.

Adhesive mounting is ideally suited for permanent applications requiring speed and ease of installation. This type of installation requires little to no layout time depending on various field conditions. Use this method if there is a potential for impact or other stresses. The adhesive method provides the strongest bond between panel and wall. Z-clip mounting is ideal for applications where frequent panel removal & re-hanging is required. This type of installation demands careful planning and layout before the panels are placed on the wall. This type of mounting method will not support more weight than the panel itself. Panels mounted with Z-clips cannot be subjected to peel away stress as this may cause a failure of panel to Z-clip bond.

Z-clip mounting is ideal for applications where frequent panel removal & re-hanging is required. This type of installation demands careful planning and layout before the panels are placed on the wall. This type of mounting method will not support more weight than the panel itself. Panels mounted with Z-clips cannot be subjected to peel away stress as this may cause a failure of panel to Z-clip bond.