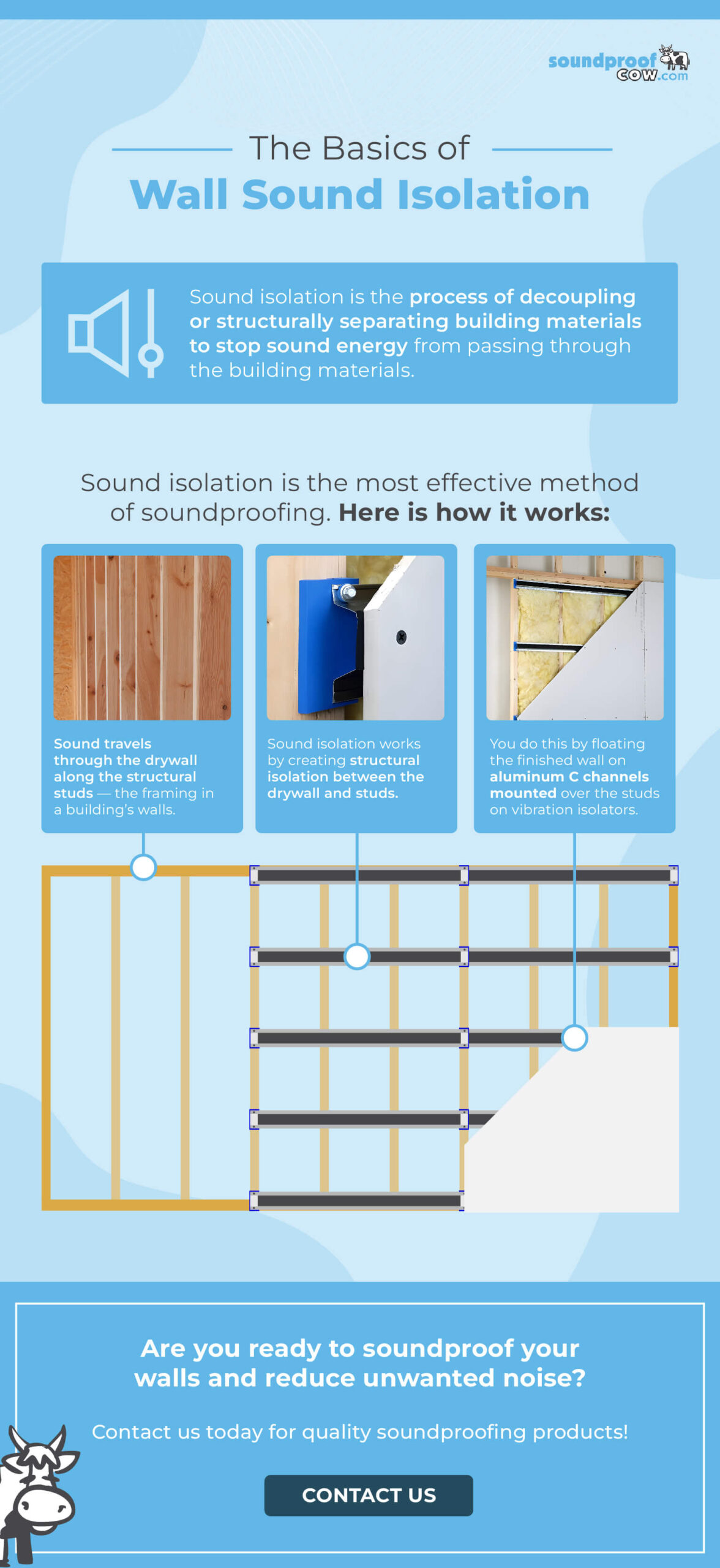

What Is Sound Isolation?

If you’re serious about soundproofing and noise reduction, sound isolation is the method for you. Sound travels through vibrations in waves. When sound waves hit a solid surface, they can work their way through and transfer from one room to the next. Sound isolation is the process of separating (also known as decoupling) assembly materials to stop the transfer of sound energy from one environment into another.

You can achieve sound isolation by creating a physical barrier between an interior and exterior space, preventing waves from passing through. Since sound can travel in more than one way, the systems used for sound isolation may vary. Resilient channels and staggered stud walls are a few examples of acoustic isolation techniques that use this principle to effectively reduce sound transmission.

The Difference Between Sound Isolation and Absorption

Sound isolation and sound absorption provide different means of improving acoustics in a space. Noise isolation involves using a sound isolation system to keep noise in one room and prevent it from traveling to another through walls, ceilings and floors. In contrast, sound absorption takes in sound waves and converts part of the energy into heat while the rest bounces back into the room.

How Wall and Ceiling Sound Isolation Works

Sound travels through drywall along common studs. Sound isolation, the most effective form of soundproofing available, works by “floating” a mounted wall over the studs using thick steel strips. These steel strips have a channeled shape and varying holes along the side. One “leg” of the steel strip is attached to a stud, while the other floats freely. The channels are attached to the frame of the wall (or ceiling) and the drywall is attached to the channel.

By using this layering technique, sound isolation works by creating a space between the drywall and the studs. There are no common studs for sound to travel along, stopping the transfer of sound waves. Another reason why sound isolation is the most effective soundproofing method is that the air space between the wall or ceiling is increased. A vibration isolation material can be installed in this air space to trap the noise sound waves. Also, sound isolation provides increased flexibility of the structure. Sound has a more difficult time traveling through flexible materials. Think of a loose string connecting two tin can telephones. It doesn’t work.

Recommended Sound Isolation Product for Walls

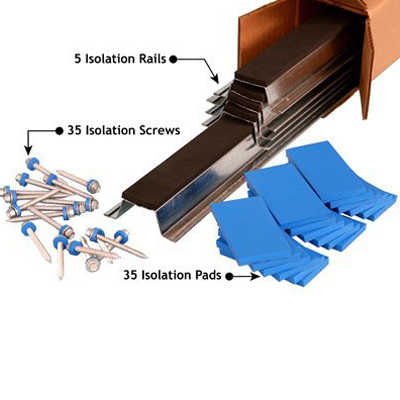

isoTRAX® Soundproofing System, the most popular sound isolation system on the market today, is fastened to the studs without any direct contact between hardware and wood. Essentially, a room within a room is formed. isoTRAX® provides a peel and stick dampener to pad the studs when applying the metal tracks. Also, each track is equipped with neoprene foam to cushion your drywall from vibration. This system is easy to install, increases wall strength, and provides top soundproofing quality.

Sound Isolation for Ceilings

You cannot completely soundproof a room without sound isolating the ceilings. While you can achieve sound isolation for your ceilings with our isoTRAX® Soundproofing System, we also recommend the isoTRAX® Soundproofing System Ceiling Package. This sound isolation system is ideal for heavier ceilings. It includes 35 elastic pads and 35 hex screws, which is double the amount in the isoTRAX® Soundproofing System.

This sound-isolating package also includes five sound-isolation rails that separate the wall from the studs, reducing impact sound. The rails prevent vibrations from affecting the soundproofing assembly.

With a system ceiling package, you can enjoy soundproofing qualities and reduced noise transfer on existing and newly constructed ceilings. You can install this package inside walls or ceilings and expect exceptional performance.

Sound Isolation for Floors

Floors are a common noise contributor. Many customers come to Soundproof Cow needing to treat flooring in high-performance home theaters, residential and professional-grade studio environments. Like walls and ceilings, floors can be floated with vibration-controlled material. Using floor sound isolation, the room “floats,” the noise vibrations are absorbed, and unwanted noise is eliminated.

We recommend Floor Joist Isolators for floor noise isolation. These U-shaped isolators are made from a medium density thermoplastic. Floor Joist Isolators work by decoupling (separating) the flooring from the structural supports. The result is a reduction of sound transmission, especially the hard-to-control low frequency sounds. The Stud Beam Isolators are sized to fit any 2X lumber product, are very easy to install and are best used for new construction when floor joists are exposed.

Sound Isolation for Doors

Doors are the largest gap (and weakest link for soundproofing) in a wall. Often the spaces around the doors leak noise. Adding to the issue is that most interior doors have a hollow core. While this makes them more cost-effective, it causes more noise problems. We offer complete soundproofing door kits for residential, commercial and industrial applications. They include all the products you’ll need to soundproof your door. For details, see Quiet Door™ Residential Door Soundproofing Kit, Quiet Door™ Commercial Door Soundproofing Kit, or Quiet Door™ Industrial Door Soundproofing Kit.

Learn More About Understanding Sound

What is Reverberation of Sound

Impact Noise vs Airborne Noise

How to Determine the STC Rating of a Wall

I have emailed a lot of different manufactures and I have to say your customer service is head and shoulders above all of them. I emailed your company at about 9pm my time and when I woke up the next morning you had already answered my question and then the follow up was a few hours later. I am impressed. Thanks a lot for the quick turn around!

- E. Gustafson