When treating a room for optimum acoustics, foam is an easy-to-install starting point. Whether you want to soundproof a home studio or entertainment room, or you’re looking to reduce noise from heavy machinery at a work site, acoustic foam can make a significant impact.

Foam panels limit echoes and reverberations in any residential or commercial setting. But what differentiates it from the everyday foam you’ll find in mattresses, pillows or couches?

At Soundproof Cow, we provide the information and materials you need for any soundproofing project. There are a few features of acoustic foam that improve its soundproofing capabilities and make it worth the investment.

Fibers for the Job

The primary difference between regular foam vs. acoustic foam is its cellular construction.

Acoustic foam is composed of open-cell polyurethane foam cut to size and shape for various applications ranging from echo reduction and sound deadening to decoration. These materials give acoustic foam unique properties, such as:

- Intentional density: Acoustical foam comes in different density levels to target specific frequencies. As density or firmness increases, the foam will absorb lower-frequency sounds. Regular foam will still absorb sound at varied frequency levels, but acoustic foam offers maximum precision.

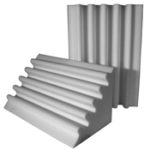

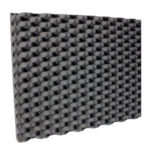

- Strategic shaping: From wedge-shaped to pyramid, square, and more, acoustic foam comes in various designs that offer different levels of reduction through increased absorptive surface area compared to regular foam.

- Peak PPI: Acoustic and regular foams have different pores per inch (PPI) ratings that describe the number and size of cells in each inch of foam. While regular foam for cushions generally has a PPI of 60-70, acoustic foam has a higher PPI closer to 80. With more cells per inch, there is more material to interact with and absorb soundwaves.

- Durability: Soundproof foam will last up to 10 years. The foam in couch cushions or mattresses may wear away, but acoustic foam is non-dusting, meaning it resists crumbling and flaking off. It’s also more resistant to accidental damage from everyday use.

- Fire resistance: Because some acoustic foam needs to be installed near electrical or ductwork, it’s designed to have a greater fire safety ratings than general foam.

- Energy efficiency: With increased density compared to regular foam, acoustic foam goes beyond sound absorption to trap heat from the inside or block it from the outside, decreasing your energy bill all year round. What’s more, many acoustic panels are made from recycled materials.

Udderly Quiet® Acoustic Foam From Soundproof Cow

At Soundproof Cow, we carry a wide variety of acoustic foam panels that rise to any commercial or residential property’s soundproofing needs. Udderly Quiet® panels come in various sizes and shapes to help you target and eliminate frequencies effectively.

Variation brings the best results, so purchase an Udderly Quiet® Acoustic Foam Kit for a full range of coverage.

View this post on Instagram

More Soundproofing Solutions

If you’re looking to soundproof your home studio, office, or work site, choose noise reduction tools designed for the greatest effect. We make acoustic treatment possible on any budget. For more information on our soundproofing materials, contact Soundproof Cow today!