Need to block sound out of your space but think you don’t have the budget for it? The cheapest ways to soundproof a wall can still be effective. Here are four ways of soundproofing your walls for a low cost.

1. Find the Noise Source and Weak Points in the Walls

Before you do any soundproofing, it’s important to understand the layout of the room itself — and know where the disruptive noise is coming from. Sounds come in various types, including airborne and impact noise, which are the most common issues driving people to soundproof their homes and businesses. While airborne noise has a middle to high frequency and travels through the air, impact noise — or structure-borne noise — can pass through windows, walls, and doors at low frequencies.

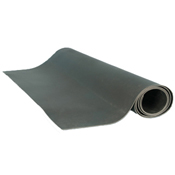

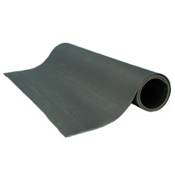

The type of soundproofing material you use depends on the type of sound and where it’s coming from. For example, if the noise is coming primarily through the window area, soundproof curtains might be enough. Or, a few acoustic panels might take care of airborne noise coming from other areas in the building. If you’re hearing low-frequency sound leaking through the walls, you’ll need a stronger installation option, like vinyl mats.

Knowing the source of the sound is also important, so you can seal the specific weak spots on the wall with materials like green glue and weatherstrip tape.

2. Fill up the Space to Soundproof Walls

Sometimes, the problem with a space is not that it picks up noise from other areas, but that it echoes noise within itself. When a room is large or sparsely furnished, the lack of objects filling up space can cause sounds to reverberate around the room, amplifying even small noises and making everything loud. This problem is simple to solve by furnishing the space with objects that will better absorb echoed sound.

Adding furniture, bookshelves and wall art to a room can reduce the nature of its echo — especially when you place the objects close to or on the walls themselves. This won’t stop exterior noise from penetrating the room, but it can quiet the reverberations within the space itself.

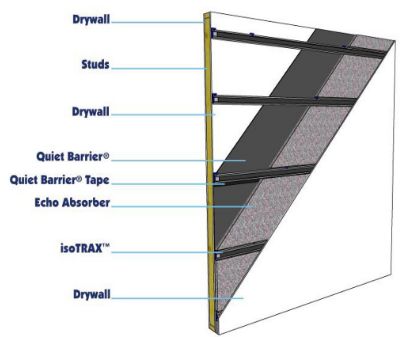

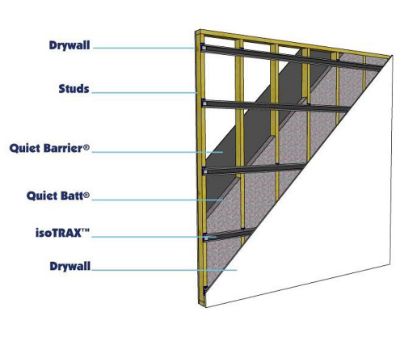

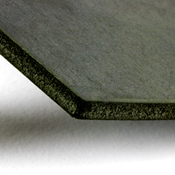

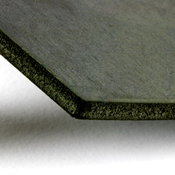

3. Install Insulation, Drywall and Acoustic Caulk for Soundproofing Walls

The best affordable way to soundproof your walls effectively is to use drywall and other materials like acoustic caulk to create an air-tight wall space. Installed over insulation and sealed in to form an extra layer in your walls, drywall forms a solid barrier for sound.

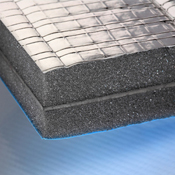

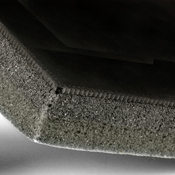

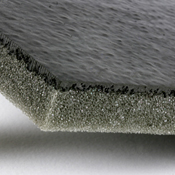

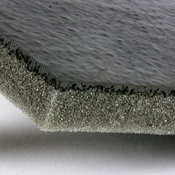

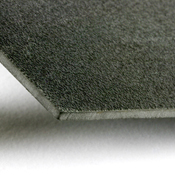

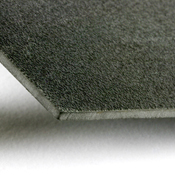

4. Supplement With Acoustic Foam Panels

If you’re thinking of using a combination of methods to improve your soundproofing, acoustic panels are a good way to add an extra layer of sound absorption. While using wall-mounted acoustic panels on their own may not be enough to stop noise from entering the room, pairing them with another soundproofing method — like drywall — can absorb additional airborne noise. With multiple soundproofing materials in place, your sound defense may improve even more.