-

Why is Factory Soundproofing Important?

- Factories typically have high ceilings with lots of hard reflective surfaces. Machinery noise bounces off these hard surfaces and back into the space. Boilers, hydraulic vats, elevator equipment, exhaust systems, punch presses, generators, engines, drills and other machines all create noise. This noise can interfere with production and ultimately cost your company money. Moreover, the noise can be hazardous to the health and safety of employees. Employees can’t communicate effectively, resulting in unnecessary accidents. And over time, exposure to loud noise can permanently damage hearing. Manufacturers come to Soundproof Cow because they want to improve their work environment, protect employees and save money on lost production. With our factory soundproofing materials, noise is reduced drastically.

-

What Can Factory Soundproofing Do for You?

- • Provide a safe work environment for employees: accidents caused by poor communication are eliminated and hearing loss is prevented • Increase productivity by decreasing distractions so your company will benefit with higher profits • Reduce complaints from neighboring buildings, allowing you to focus on what’s most important

When it comes to a work environment, how loud is too loud? According to the Occupational Health and Safety Administration (OSHA), it’s likely too loud in a factory or other workplace if people need to shout to be heard when talking to others standing just a few feet away. In addition, noise may be an issue if workers hear humming in their ears or have temporary hearing loss after they leave work.

Factories can be among the loudest places to work. Fortunately, there are ways to soundproof a factory to reduce industrial noise levels and allow your employees to be more productive and healthy.

Factory Soundproofing Products

Factory Sound Absorption Products

-

Acoustic Foam Panels

Shop Now -

Acoustic Partitions

Shop Now -

Echo Absorber™ Acoustic Cotton Panels

Shop Now -

Fabric Wrapped Acoustic Panels

Shop Now -

Fabric Wrapped Foam

Shop Now -

Fire Rated Acoustic Foam

Shop Now -

Fire Rated Foam Panels

Shop Now -

Hanging Baffles

Shop Now -

Quiet Board™ Water Resistant Panels

Shop Now -

Soundproofing Foam

Shop Now

Reasons to Soundproof Your Factory

To minimize the risk of hearing loss, OSHA recommends employees spend no more than eight hours a day exposed to noise levels over 85 decibels. Machines such as printing presses produce noise that averages 85 decibels. In comparison, a normal-volume conversation is around 60 decibels, and a night club with music is over 95 decibels.

Exposure to loud factory machine noise does more than put a worker’s hearing at risk. It can also have effects on people’s health. One study found a connection between high noise levels on the job and increased incidences of high blood pressure and elevated cholesterol. One reason for the connection might be that loud environments increase people’s stress levels. Over time, elevated stress levels can contribute to health conditions, such as heart disease and high blood pressure.

Along with protecting your employees’ health, soundproofing industrial machines and factories can also help reduce the risk of accidents and injuries on the job. When the environment is too loud, workers might not be able to hear alarms or shouted warnings from their co-workers, putting them at increased risk of injury.

Loud factory machine noise can also interfere with concentration and reduce employees’ productivity, ultimately having an impact on a company’s bottom line.

Ways to Reduce Noise in Factories

OSHA describes two types of controls a company can use to reduce noise levels in the workplace: engineering and administrative. Engineering controls include changes to the equipment or environment to lower noise levels, while administrative controls are changes to schedules or the workplace that help to make things quieter. A few things to do to reduce industrial noise include:

- Isolate or enclose the noise: One way to reduce noise is to enclose the equipment that is the loudest. An enclosure, such as an acoustic partition or panel, creates a barrier around the equipment. This enclosure minimizes the noise that is allowed out, while still allowing people access to the machinery.

- Create a barrier around the noise: Another way to lower noise levels is to create a barrier between the noisy piece of equipment and the person who needs to operate it. For example, a machine can be placed near a wall covered in foam panels to help absorb the noise.

- Update machinery: In some cases, updating the equipment used in a factory can help diminish levels. Older pieces of equipment may be louder than newer models — either due to the design of the equipment or as a result of wear and tear.

- Maintain machinery and equipment: Maintaining equipment in the factory can help to lower noise levels. As machines are used regularly, wear and tear can cause them to produce more noise while they run. Oiling machines and adjusting gears and other parts as needed can allow them to run more smoothly and quietly.

- Run loud machines when no one is around: An administrative change can help to lower noise levels in a factory during the times when most employees are on the job. Running the loudest pieces of equipment during times when few people are on the factory floor can help to create a more comfortable work environment.

- Give employees breaks: While giving employees time away from a noisy factory floor won’t reduce the volume of the factory itself, it can help to protect workers. Another option is to provide workers with hearing protection, such as earplugs or earmuffs. When employees do get a break, it should be in a quiet area that is insulated from the sound of the factory equipment.

- Create space between employees and equipment: Distance can also help to lower sound levels in a noisy factory. If you can double the space between employees and the equipment they use, you can lower sound levels by 6 decibels. Installing baffling and acoustic panels and increasing the space between machines and employees can help to lower sound levels further.

Best Products to Soundproof Your Factory

Soundproofing your factory can help promote increased productivity and profits. There are several products available that absorb sound or effectively block noise. Get to know some of the best soundproofing products that could improve your factory environment:

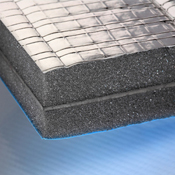

- Quiet Barrier® Specialty Composite: Quiet Barrier® Specialty Composite has four layers that provide the most soundproofing power. Its thick layer of foam absorbs sound at all frequencies, while a thinner layer below blocks vibrations and airborne noises to further reduce sound.

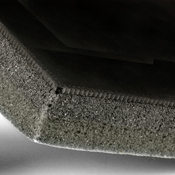

- Quiet Barrier® MD Soundproofing Composite: A medium-thick foam, the Quiet Barrier® MD Soundproofing Composite combines a layer of noise-controlling material with soundproofing foam. It’s ideal for creating sound-insulated areas, such as offices or break rooms that are attached to noisy factory floors.

- Quiet Barrier® HD soundproofing material: Quiet Barrier® HD soundproofing material is sold in a roll and offers both sound-dampening and soundproofing functions.

- Acoustic Partitions: Acoustic partitions are portable walls that absorb and block sound. You can set them up around loud pieces of equipment to help isolate noise in a factory.

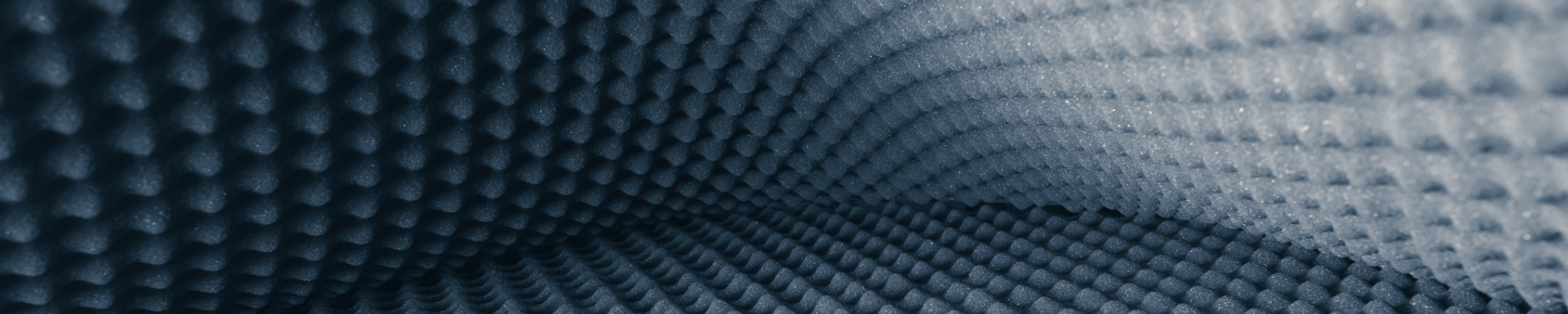

- Acoustic foam panels: If you need a budget-friendly, quick fix, acoustic foam panels might be the right option for your factory. The panels are peel-and-stick and help to minimize reverberation, absorb sound and keep sound from escaping a room.

- Acoustic hanging baffles: In factories with high ceilings, sound waves have plenty of room to travel and reverberate. Hanging acoustic baffles from the ceiling can help lower volume levels by keeping sound from bouncing around.

- Class A or Class 1 acoustic foam: If you’re looking for superior soundproofing and fire protection rolled into one, you can’t go wrong with Class A or Class 1 acoustic foam, which blocks sound while providing top-level fire protection.

Purchase Soundproofing Products to Reduce Industrial Factory Noise Levels

Soundproof Cow offers a wide range of soundproofing and sound absorption materials that can help to create a more comfortable and productive work environment for you and your employees. To learn more about our products and for guidance on the soundproofing methods that will work best for you, contact us today.

Soundproof Other Spaces

The times I talked with you on the telephone and corresponded through email you have been very helpful and efficient. I would highly recommend Soundproofcow.com to anyone!

- S. Cimino